- #Post processor powermill configuration update

- #Post processor powermill configuration manual

- #Post processor powermill configuration full

- #Post processor powermill configuration software

- #Post processor powermill configuration license

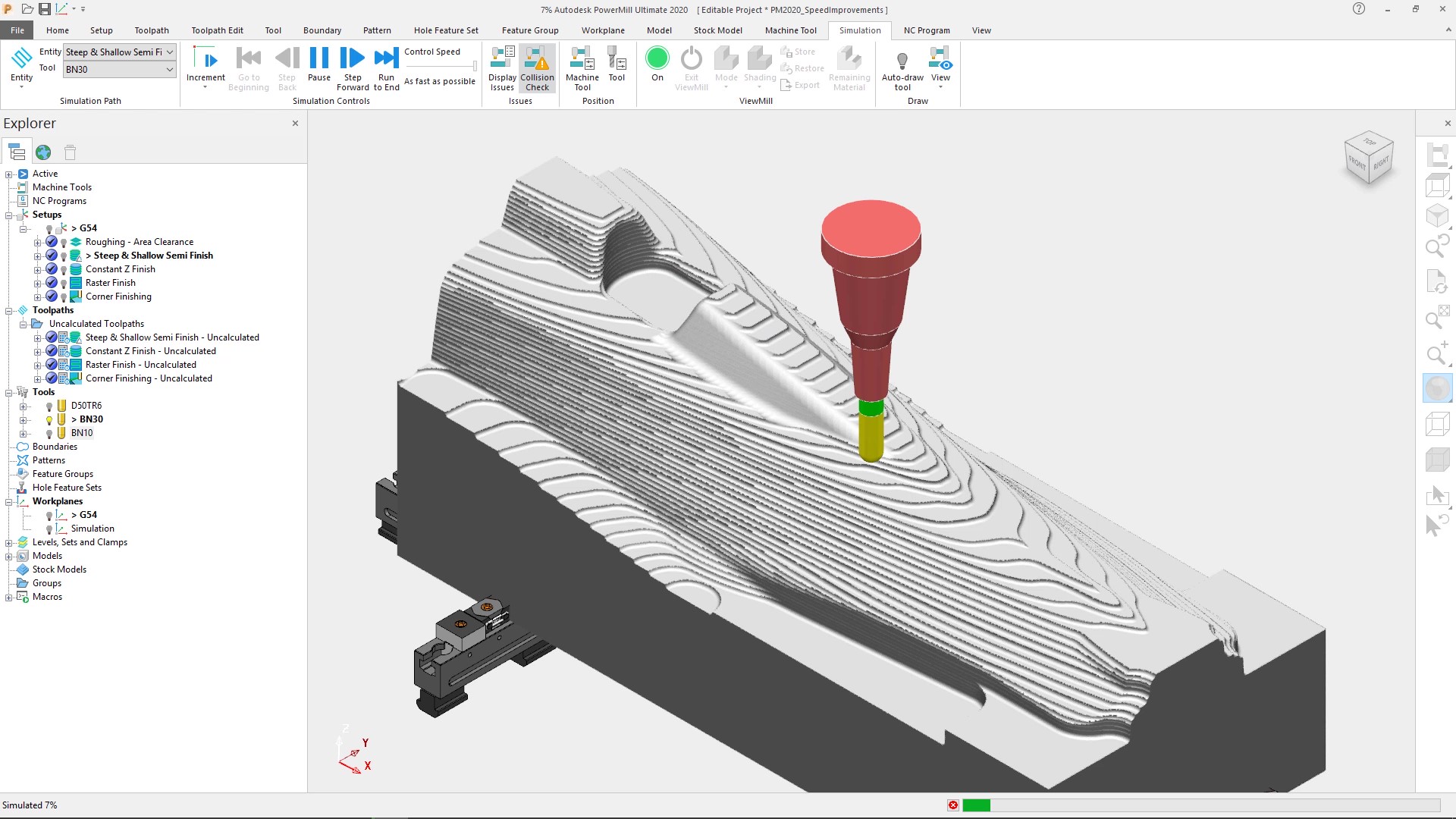

This could result in additional toolpaths being required or even parts needing additional, manual polishing. When using the automatic collision avoidance option, there were, unfortunately, rare occasions when a toolpath would be processed that was either incomplete or fragmented. In these cases, it was possible to machine the undercut either, a) using a lollipop or disk cutting tool (great if you only have a 3-axis machine tool), or b) by using PowerMill’s automatic 5-axis collision avoidance. Some releases ago, PowerMill’s Constant Z finishing toolpath type was updated to allow it to handle parts containing undercuts. This latest release of PowerMill now produces more accurate toolpaths – reducing the risk of material being left un-machined and helping to avoid the need for manual polishing. These small errors could result in material being left un-machined which would need to be removed later – either using additional toolpaths or by manual polishing. In previous releases of PowerMill, there were occasions where the toolpath could contain chamfers in internal corners. And it is here, where we see the next improvement in PowerMill 2022 – namely improved toolpath accuracy. In most cases, this is best achieved using a Flat Finishing toolpath (either Rasteror 3D Offset). In the previous PowerMill update, Autodesk discussed excluding flat areas from Steep & Shallow toolpaths – but these areas still need to be machined. Instead, PowerMill simply calculates a toolpath with the flat areas removed – simple!

#Post processor powermill configuration update

This small, but significant update means programmers no longer need to spend time creating separate boundaries to limit the machining. PowerMill 2022 includes a new option to exclude flat areas during toolpath calculation. PowerMill’s most commonly used feature – finishing toolpaths (Steep & Shallow, Raster, and 3D Offset Finishing) has been improved to simplify the programming of parts containing flat/planar areas. Finishing Toolpaths now Exclude Flat Areas In this blog, we’ll provide a brief overview of the major highlights as well as offering links for those that want to learn more. Following recent releases, this specific update includes a healthy mix of fixes, improvements, and new capabilities aimed at simplifying the daily life of CAM programmers around the world. The Autodesk PowerMill development team has just released the latest update to Autodesk’s CAM software.

It can edit blank documents but if you want special formatting capabilities you have to pay $750 for a formatting processor. Is a CAM program a CAM program if it doesn't have a way to support your machine the way you want to without bleeding more money out of you? Imagine if you had to pay money to create a resume with Microsoft Word.

Each and every cycle back and forth with the VAR doing the editing means having to wait for the update (if it is important enough) and possibly making some changes to existing part programs. Why? As someone pointed out earlier, they are on version 25 of their post processor.

#Post processor powermill configuration software

Shitty software that doesn't allow you to easily edit and configure your own post processor cost you money. There's another side to this, which is the productivity hit.

#Post processor powermill configuration full

And, of course, you know very well that a company like GoEngineer has already produced posts for the VF2 so they are charging you full tilt to more than likely just email you a copy of an already existing post processor. I can't believe they are charging every VF2 owner $750 to effectively reinvent the wheel. For everything else these companies need to invest the time to develop a sensible starting point and even a few options from there. Getting CAMWorks years ago may have been a mistake as most people I know are using MasterCAM. How is it with other CAM packages? I might consider switching just on the principle of it all. It has these generic post processors you can play with and that's it. The CAM software ought to come out of the gate with a library of supported machines. But for a Haas machine? Or any other common machine out there? This is nothing less than despicable to me. Someone might have to devote some time to configure it. I can understand charging to configure a post processor for an oddball machine.

And now I am told by GoEngineer it'll cost $750 to get the code.

#Post processor powermill configuration license

So.I paid-up to renew my license and give it another try rather than going to, say, MasterCAM. I bought it back in 2008 and haven't used it since 2010 after I closed my business.

0 kommentar(er)

0 kommentar(er)